English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

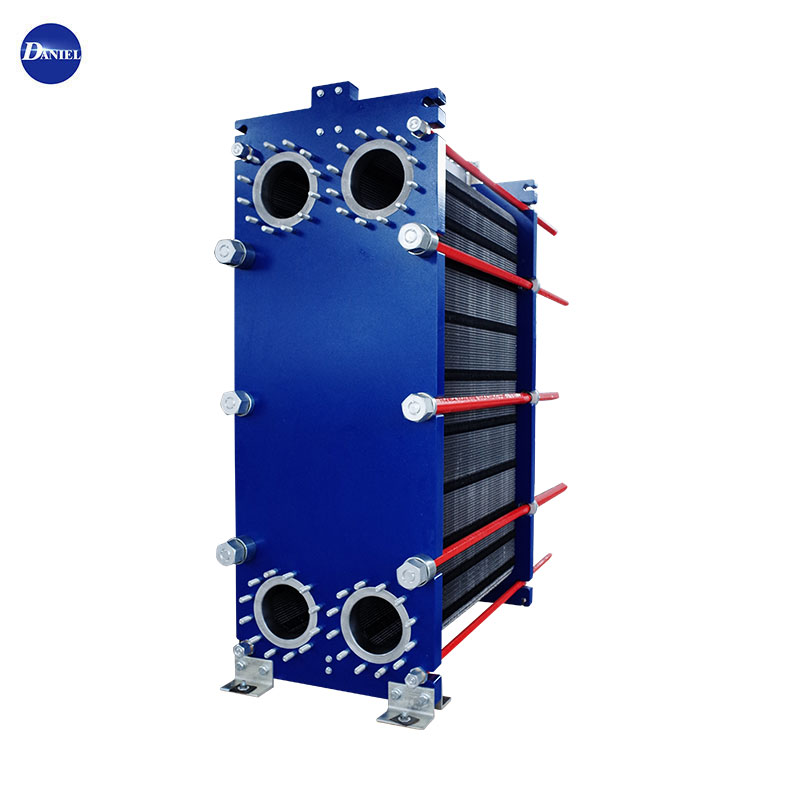

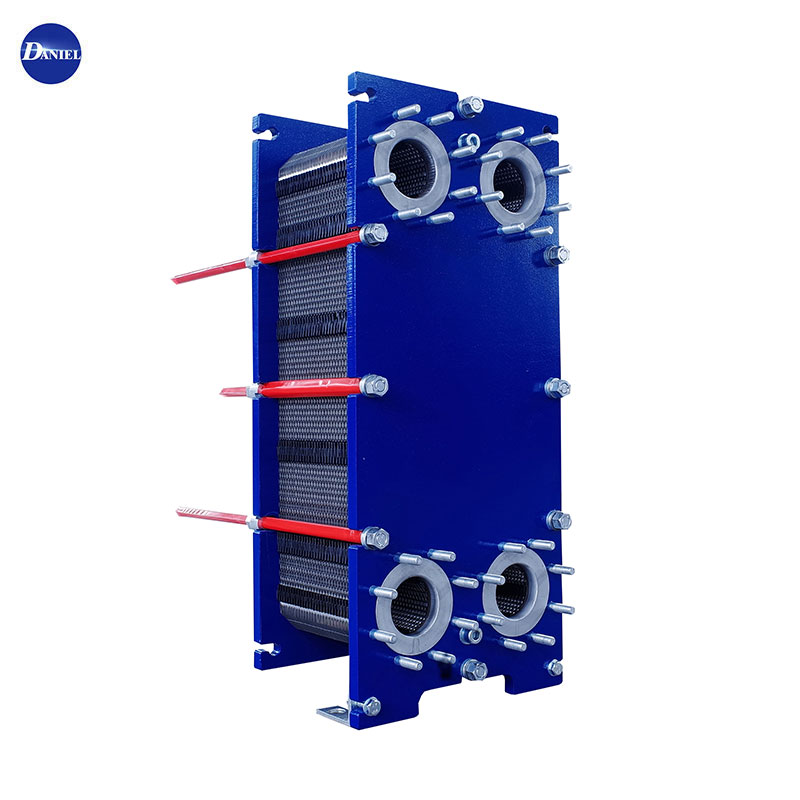

Lumahing gula penyemptan panas lan pasteurisasi produksi susu

Kirim Pitakonan

Lumahing gula penyemptan panas lan pasteurisasi produksi susu

| Model | Bh30 | Bh60b / bh60h | Sh60h | Lb100B | |

| Referensi Cross | M3 | M6, M6m | Ts6m | Tllob | |

| Dhuwur, H [MM] | 480 | 920 | 940 | 704 | 1885 |

| Jembar, w [MM] | 180 | 320 | 330 | 400 | 480 |

| Minstandardlength, l [mm] | 400 | 500 | 500 | 530 | 850 |

| Dawane Lengkap Standard, L [MM] | 650 | 1500 | 1500 | 1430 | 2350 |

| VerticalportDisance, vc [mm] | 357 | 640 | 640 | 380 | 1338 |

| Horisontal Publangka, HC [MM] | 60 | 140 | 140 | 203 | 225 |

| Suhu maksimal [℃] | 180 | 180 | 180 | 180 | 160 |

| Tekanan Max [BARG] | 16 | 10 | 16 | 16 | 10 |

| Pipa Ukuran Flange | Pipa 1 1/4 " | DN50 / 2 " | DN50 / 2 " | DN65 / 2 " | DN100 / 4 " |

| Max. Rating aliran [kg / s] | 4 | 16 | 20 | 50 | |

| Model | Bh100b / bh100h | Bh150b / bh150h | Bh200h | ||

| Referensi Cross | MLOM, M10B | M15m, m15b | M20m, T20m, T20B | ||

| Dhuwur. H [mm] | 1084 | 1084 | 1885 | 1885 | 2150 |

| Jembar, w [MM] | 470 | 470 | 610 | 650 | 750 |

| Min standar, L [MM] | 700 | 700 | 1150 | 1150 | 1250 |

| Dawane Lengkap Standard, L [MM] | 2300 | 2300 | 2050 | 3250 | 3350 |

| Portdistance Venical, VC [MM] | 719 | 719 | 1294 | 1294 | 1478 |

| Horisontal Port Jarak, HC [MM] | 225 | 225 | 298 | 298 | 353 |

| Temparrature Max [℃] | 180 | 180 | 180 | 180 | 180 |

| Tekanan Max [BARG] | 10 | 16 | 10 | 16 | 42659 |

| Ukuran flang | DN100 / 4 " | DN100 / 4 " | DN150 / 6 " | DN150 / 6 " | DN200 / 8 " |

| Max. Rating aliran [kg / s] | 50 | 80 | 225 | ||

| Model | Sh200b | BH250 | Bh300h | ||

| Referensi Cross | TS20M | Mx25b | M30 | ||

| Dhuwur. H [mm] | 1405 | 2595 | 2920 | ||

| Jembar, w [MM] | 740 | 920 | 1190 | ||

| Min standar, L [MM] | 900 | 1550 | 1650 | ||

| Dawane Lengkap Standard, L [MM] | 2700 | 3350 | 5200 | ||

| Portdistance Venical, VC [MM] | 698 | 1939 | 1842 | ||

| Horisontal Port Jarak, HC [MM] | 363 | 439 | 596 | ||

| Temparrature Max | 180 | 180 | 180 | ||

| Tekanan Max [BARG] | 42659 | 42659 | 42659 | ||

| Ukuran flang | DN200 / 8 " | DN200 / DN250 / 8 "/ 10" | DN300 / DN350 / 12 "/ 14" | ||

| Max. Rating aliran [kg / s] | 190 | 250 | 250 | 497 | |

Wilayah aplikasi:

HVAC: Nyedhiyani pemanasan kantor, pabrik, bangunan omah, hotel, restoran, pemanasan lan sumber banyu, pemanasan lan penyembuhan sistem udhara.

Industri wesi lan baja: Penyejuk, mesin casting sing terus-terusan, penyejuk minyak hidraulik, adhem emulsi, penyejukan banyu tungku.

Perawatan lumahing: Penyejukan elektrolit, penyejukan cat, penyejukan larutan fosfat.

Industri Automobile: Penyejet minyak sing nyenengake, penyejukan cat, perawatan fosfat cairan adhem.

Alkohol lan pangolahan jeroan jagung: Penyejukake cairan, penyejukan saccharifikasi, penyejukan pecah anggur, penyejukan metanol, kepencut methanol, lan macem-macem anggur.

Petroleum lan Petrokimia: Pemanasan lan Penyemasan produk minyak, piranti pendinginan banyu sing akeh didalekake.

Daya Nuklir Power: banyu siram tertutup, pendinginan pulo nuklir saka tanduran tenaga nuklir, bantu sistem sumber banyu, pompa vakum diisi unit.

Industri Kimia Batu: Penyejukan gas batu bara, Penyejukan minyak amonia, penyejukan banyu sampah, kondensasi banyu benzene, tambahan banyu adus

Janji industri kimia janji: macem-macem obat sing cair, pemanasan banyu murni, pendinginan, penguapan, kondensasi lan sterilisasi.

Industri kimia organik: macem-macem asam anorganik, alkali, pemanasan uyah, penguapan, kondensasi, penyejukan asam laras, pemanas macem-macem konsentrasi lan piranti pemulihan panas kanggo proses desalinasi.

Hadiah Farmasi: Kelangan emulsion, penyejukan plasma, penyejukan infus, penyejukan antibiotik ,HARI CLOYE CLIEN.

Industri panganan: Raw Pemanasan Jus, Pemanasan senggol, pasteurisasi susu lan pendinginan susu, pemanasan jus karbonat, macem-macem pemanasan anggur lan pendinginan anggur.

Marine lan Mesin: Kelangan tengah, pelumik minyak pelumas, pendinginan coolant piston, penyejukan minyak sing abot, pemanasan banyu laut, pelumangan banyu laut, pemanasan tank ngisor.

Industri metalurgi: jeblugan jurang, casting terus-terusan, adhem banyu sing ditutup, macem-macem minyak pelumas lan adhem emulsion, penyejukan minyak transmisi.

Perawatan banyu lan Desalination: Aplikasi sistem membran, perawatan banyu mikroba, pemurnian banyu, sing resiktrasi.

FAQ

P: Apa aku bisa duwe conto conto?

A: Ya, kita welcome conto supaya bisa nyoba lan mriksa conto conto kualitas sing bisa ditampa.

P: Apa wektu timbal?

A: Conto mbutuhake 1-3 dina, produksi produksi massal 7-15 dina, uga miturut volume urutan.

P: Apa sampeyan bisa nampa kumpulan campuran saka macem-macem produk?

A: Ya, kita ndhukung macem-macem Grosir campuran produk.

P: Kepiye sampeyan ngirim barang lan suwene suwene?

A: Kanggo conto conto, biasane kita ngirim DHL, UPS, FEDEX utawa TNT.Nate biasane mbutuhake 3-5 dina teka.

P: Apa sampeyan bisa menehi backer wadhah ing kasus kayu yen aku pesen luwih akeh?

A: Ya, kita bisa nyedhiyani set produk kemasan kayu, nanging mung ana ing jumlah gedhe.

P: Kita pengin ngunjungi perusahaan sampeyan?

A: Ora ana masalah, kita minangka produksi lan perusahaan ngolah, ngarepake rawuh lan kita bakal nuntun sampeyan kanggo ngunjungi pabrik lan pabrik pabrik.